Research and development

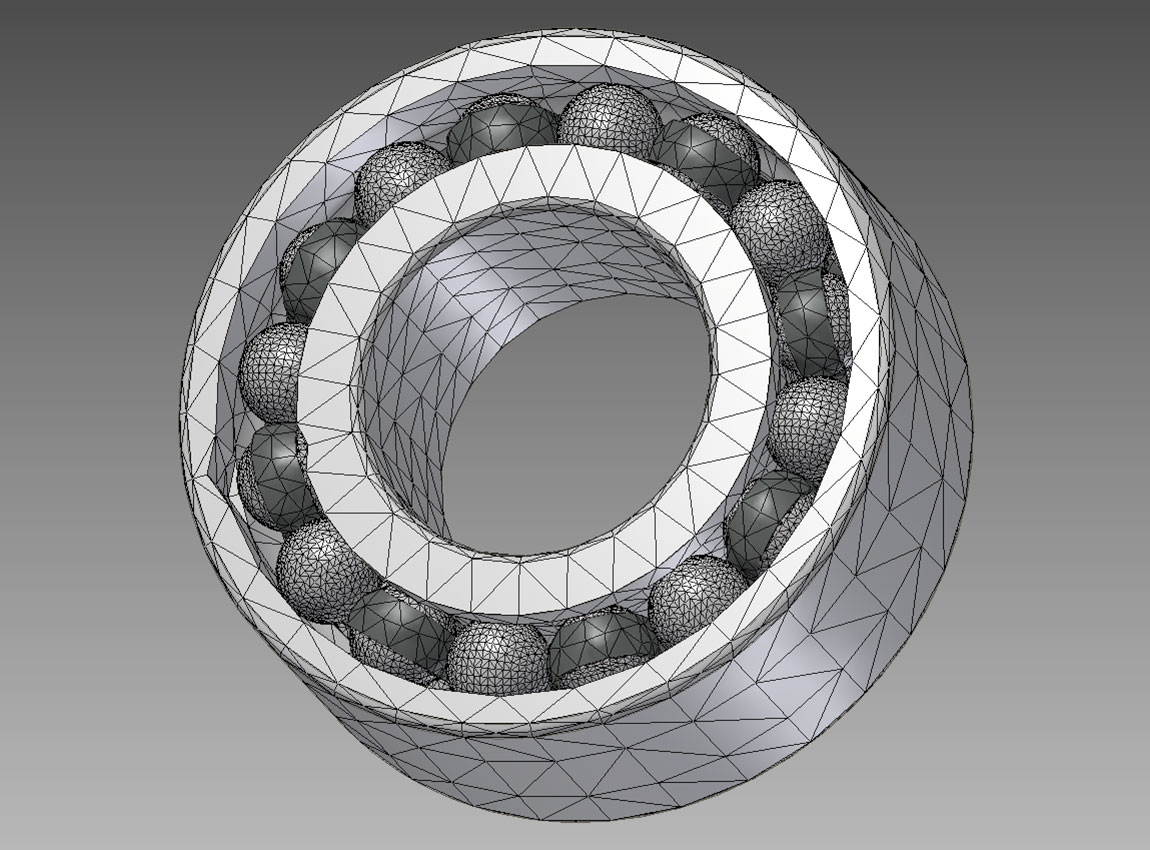

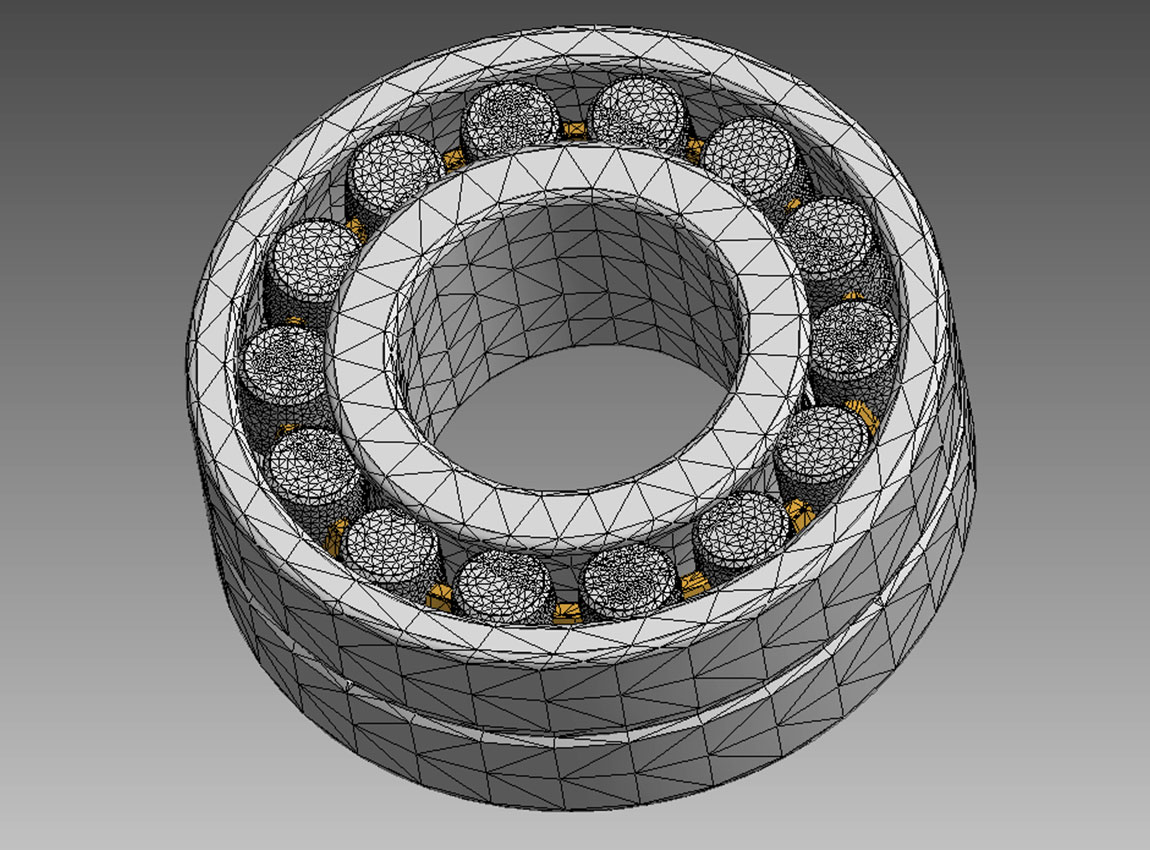

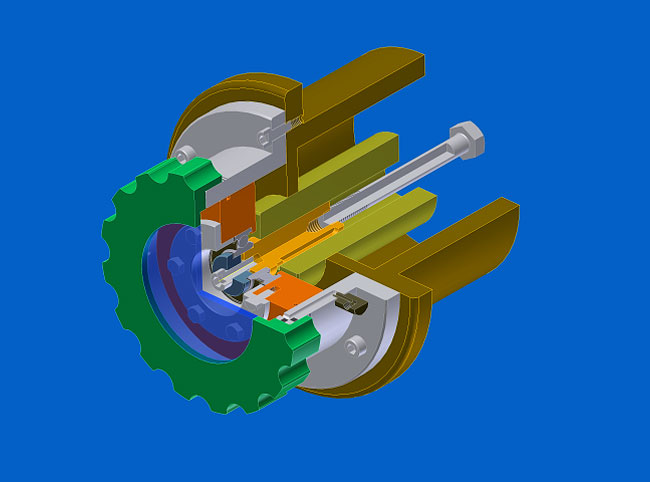

At designing and developing new products we use the latest construction systems CAD and 3D CAD, and their quality is evaluated by precise measuring equipment and we them test them by simulating in real operation. We cooperate with external organizations, testing organization, laboratories and technical universities, if necessary. Our main target is to offer our customers an optimal solution and meet their requirements in terms of innovation, design and use of bearings in operation.

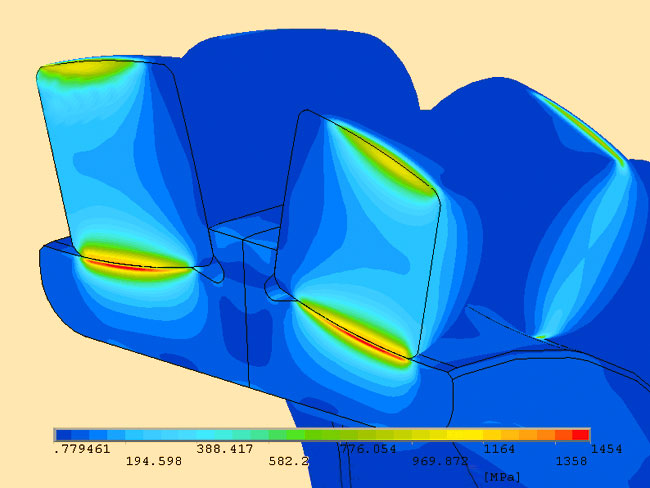

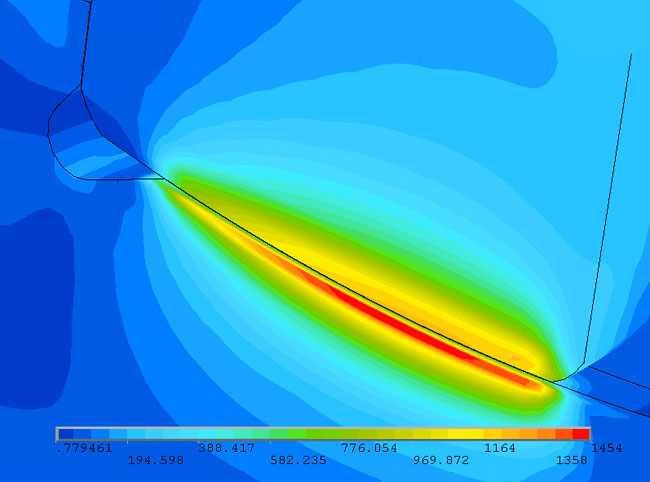

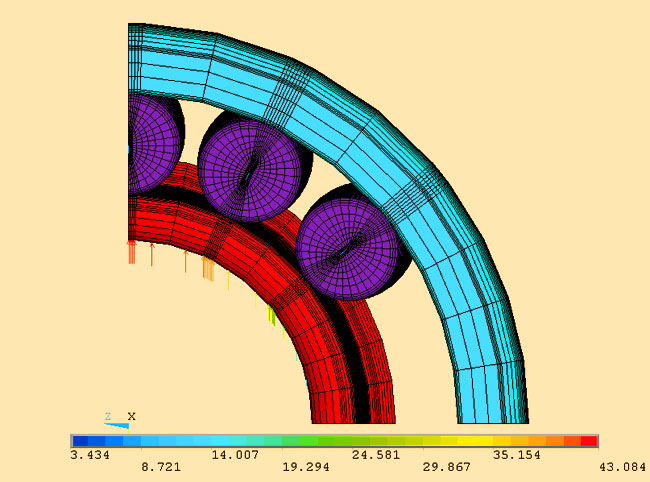

Our design department aim at analysis of mutual interaction of individual bearing components, reactions in rolling contact points and impact on bearing properties depending on the operation conditions. Modern CAD systems, experiences of employees and cooperation with suppliers’ technological departments and other external organizations allow us to improve individual bearing characteristics – shape of race ways, tribology conditions, rolling bodies, cages in order to achieve maximal space for bearing and improvement of its final properties – basic dynamical load of bearing, rated rotational frequency, friction torque, and vibration level. Determining and calculation of these parameters is a function of the material used, the size and number of rolling bodies, the contact angle and the bearing central diameter.

Български

Български Česky

Česky Deutsch

Deutsch English

English Español

Español Français

Français Polski

Polski Русский

Русский Slovensky

Slovensky Український

Український